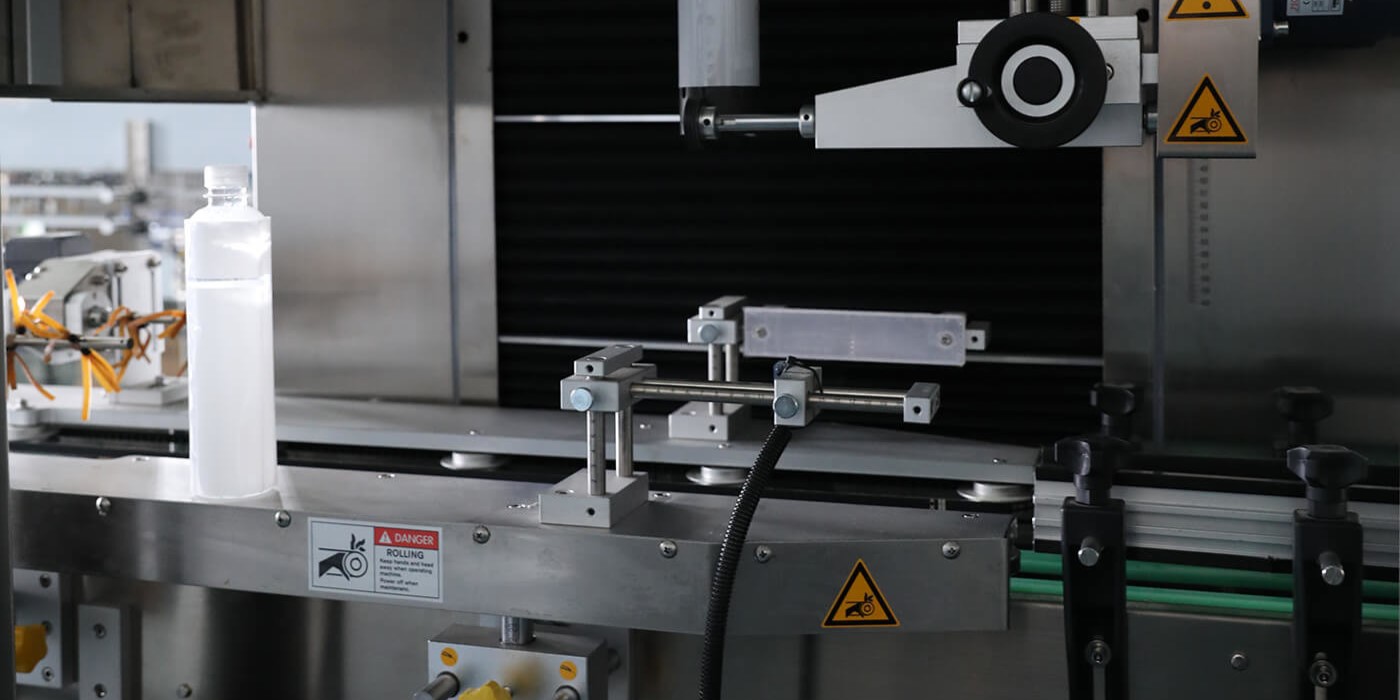

When it comes to labeling products, shrink sleeve labeling is an increasingly popular option for businesses. An automatic shrink sleeve label machine allows businesses to quickly and efficiently apply professionally printed labels onto the containers of their products. When purchasing a shrink sleeve label machine, there are several key factors that need to be considered in order to ensure that the machine can meet your business’s needs. We will cover important topics such as speed, quality of output, ease of operation and maintenance, compatibility with other equipment and cost-effectiveness, in order to help you find the right automatic shrink sleeve.

1. Speed:

When selecting an automatic shrink sleeve labeling machine, speed should be one of the primary considerations. How quickly can the machine apply labels? Depending on the size and complexity of your products, you may need a faster or slower model. Additionally, if you are using more than one type of label, you’ll want to make sure that you have a machine with enough adjustability to accommodate different sizes and types of labels.

2. Quality of Output:

Another important factor is the quality of output from the machine. You’ll want to ensure that each label is applied correctly and consistently for a professional look every time. Check for features such as adjustable speed settings and tension controls which will allow you to fine-tune the output. If you are working with sensitive materials such as food or medical products, you’ll also want to ensure that the machine is able to produce labels of a consistently high quality.

3. Ease of Operation and Maintenance:

It’s important to find a machine that is easy enough for your staff to operate without needing excessive training. Additionally, check that the machine is relatively simple to maintain; look for features such as automatic cleaning systems and self-diagnostics which can help reduce manual labor costs and extend the life of your equipment.

4. Compatibility with Other Equipment:

If your business already uses other labeling equipment such as barcode scanners or printers, it’s important to make sure that any new shrink sleeve labeling machines are compatible with this existing equipment. This will ensure that you can integrate your new machine into your existing production line and reduce any disruptions to your workflow.

5. Cost-Effectiveness:

Finally, when selecting an automatic shrink sleeve labeling machine it’s important to consider the total cost of ownership. This includes factors such as initial capital outlay and running costs, as well as the availability of spare parts and service contracts for maintenance or repairs if required. By taking all these factors into account, you’ll be able to find a machine which is both reliable and cost-effective in the long run.

Conclusion

By taking the time to consider each of these factors, you can make sure that you choose an automatic shrink sleeve labeling machine which is suited to your business’s specific needs and requirements. With the right machine in place, your business will be able to produce labels of a consistently high quality quickly and efficiently.

Oscar

Oscar is a hard-working individual who excels in business. He has been working in the same company for many years and has climbed the ranks to become one of the top employees. Oscar is dedicated to his work and takes great pride in providing value to his team and customers. He is an excellent problem solver and always looks for ways to improve efficiency and productivity. When he's not working, Oscar enjoys spending time with his family and friends. He loves being active outdoors, playing sports, and exploring new places.